Isuzu 2006 Annual Report Download - page 17

Download and view the complete annual report

Please find page 17 of the 2006 Isuzu annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

15

Isuzu Motors Limited Annual Report 2006

Our environmental management vision

As an industry leader in environmental responsibility, we

take a two-pronged approach—developing cleaner vehicles

and minimizing the environmental burden of our manufac-

turing facilities. Isuzu currently has three steps in developing

environmental products in terms of timeframe. In the short

term, since diesel engines are fuel-efficient, we are working

to make emissions cleaner while maintaining their advan-

tages. In the medium term, we aim to reduce CO2 emissions

by making our products more fuel-efficient, and in the long

term, from an energy security perspective, we are starting

to reduce our dependency on fossil fuels.

Reducing environmental impact (product lifecycle)

Over 90% of the environmental impact caused by auto-

mobiles occurs during their use, and most of that impact

consists of exhaust emissions such as particulate matter

(PM), NOx and CO2. Isuzu tackles the challenge of reducing

emissions from the “hard” and “soft” aspects of our busi-

ness. The “hard” aspect is developing clean diesel engines,

while the “soft” aspect includes driver education programs

on safety and fuel-efficient driving.

Isuzu works on reducing environmental impact of its vehi-

cles and manufacturing facilities throughout the product life

cycle. In addition to the efforts involved in the Team Minus

6% project, there are initiatives during the manufacturing

stage to reduce industrial waste, managing and reducing

environment-impacting substances, preventing air and water

pollution, and encourage efficient resource use. At the dis-

posal and recycling stage, Isuzu is active in recycling efforts

such as improving vehicle disassembly and waste separation,

reusing recycled materials and parts, and minimizing waste.

Environmental management/audit system

To tackle the environmental issues throughout the Isuzu

group worldwide, we initiated a Consolidated Environmental

Management System to regulate the activities of financial-

ly consolidated domestic and overseas manufacturers and

sales companies, including subsidiaries and equity-method

companies. The goal of Isuzu’s Environmental Management

System is continual reduction of the environmental impact

caused by our business activities and to strengthen the

company’s environmental controls. We distribute the Isuzu

Charter on the Global Environment to group companies to

ensure the spread of our environmental activities worldwide.

Isuzu conducts annual audits to ensure that the

Environmental Management System is being implemented

correctly and to evaluate progress. There are one or two

internal environmental audits per year, and monitoring and

reviews by third-party certifying organizations. All domestic

plants and the Engineering Division were monitored in fiscal

2004 and no problems were found.

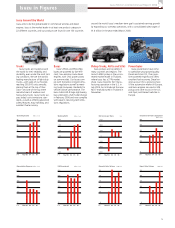

Environmental-friendly products (ELF CNG, hybrid)

The two mainstay eco-friendly vehicles in Isuzu’s current

product range are hybrid and compressed natural gas (CNG)

powered vehicles. The ELF CNG-MPI is the latest model of

Japan’s best-selling CNG vehicle, with approximately 70%

market share. With its multipoint injection (MPI) system with

highly precise electronic controls, the new ELF CNG-MPI be-

came the first vehicle in Japan to meet the CNG vehicle emis-

sions standards of the New Long-Term Emissions Regulations.

This model achieved the cleanest exhaust emissions of all clean

energy vehicles. It produces virtually no PM or black smoke

emissions, and boasts low-noise performance, making it ideal

for early morning and late evening deliveries in urban areas.

Diesel hybrid vehicles are highly fuel-efficient and emit

low levels of CO2. The ELF Hybrid is a practical clean energy

vehicle with no facilities constraints in that it can use existing

diesel refueling facilities. Featuring the newest diesel engine

and a hybrid system optimal for light-duty vehicles, it is as-

sisted by an electronic motor and highly efficient to operate.

Compared with the 2003 emissions regulations, fuel con-

sumption was reduced by 35%, CO2 emissions by 25%, PM

by 85%, and NOx by more than 25%. The ELF Hybrid offers

10–20% better fuel efficiency and 9–17% less CO2 emis-

sions than current diesel models in general city driving.

Environment-friendly plants

An example of Isuzu’s ongoing efforts to reduce environ-

mental impact is the upgrading of the cogeneration system

at the Fujisawa plant, which is Isuzu’s main manufacturing

plant. The new cogeneration system replaces the first system

introduced in 1991, which used a turbine powered by natu-

ral gas to generate electricity and reused the waste heat to

generate additional electricity and steam for plant air-condi-

tioning and some production processes. Isuzu improved the

efficiency of the system’s power generation by replacing the

turbine with a gas-powered engine. The fuel for the system’s

boiler was also changed from heavy oil to natural gas. As a

result, the new system consumes 4.3% less energy and re-

leases 10.2% less CO2 emissions than the previous system.

The power output has increased 4.5 times to 18MW/h.

Social Responsibility

Isuzu addresses its responsibility to local and wider com-

munities in multiple ways. In Japan, we take part in local

events, support community service initiatives like working

with the disabled, and participate in environmental clean-up

activities. We engage in similar activities overseas.

Isuzu group and its employees have also been active in pro-

viding financial and material assistance to the victims of earth-

quakes and tsunamis, floods and landslides, and weather and

other calamities—all around the world. Since 2004, they have

given over ¥90 million, beginning with ¥23 million in cash do-

nations and materiel following the October 2004 earthquakes

that struck Niigata, Japan, and extending to ¥1.5 million for

the victims of February 2005’s mudslides in the Philippines,

¥7.2 million for those affected by Hurricane Katrina in the

U.S. in September 2005, ¥5.6 million for the victims of the

October 2005 earthquakes in Pakistan, and—most recent-

ly—¥12 million to help the people of central Java recover from

the May 27, 2006, earthquake and its aftershocks. Most sig-

nificantly, Isuzu group and its employees contributed some

¥41 million in cash, materiel, and labor (including traveling re-

pair teams to fix broken down vehicles) to help those whose

lives were affected by the December 2004 earthquakes off

Sumatra (Indonesia) and the resulting tsunamis.