Halliburton 2011 Annual Report Download - page 18

Download and view the complete annual report

Please find page 18 of the 2011 Halliburton annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.3

Research and development costs

We maintain an active research and development program. The program improves products,

processes, and engineering standards and practices that serve the changing needs of our customers, such as

those related to high pressure/high temperature environments, and also develops new products and

processes. Our expenditures for research and development activities were $401 million in 2011, $366

million in 2010, and $325 million in 2009, of which over 96% was company-sponsored in each year.

Patents

We own a large number of patents and have pending a substantial number of patent applications

covering various products and processes. We are also licensed to utilize patents owned by others. We do

not consider any particular patent to be material to our business operations.

Seasonality

Weather and natural phenomena can temporarily affect the performance of our services, but the

widespread geographical locations of our operations mitigate those effects. Examples of how weather can

impact our business include:

- the severity and duration of the winter in North America can have a significant impact on

natural gas storage levels and drilling activity;

- the timing and duration of the spring thaw in Canada directly affects activity levels due to

road restrictions;

- typhoons and hurricanes can disrupt coastal and offshore operations; and

- severe weather during the winter months normally results in reduced activity levels in the

North Sea and Russia.

Additionally, customer spending patterns for software and various other oilfield services and

products can result in higher activity in the fourth quarter of the year.

Employees

At December 31, 2011, we employed approximately 68,000 people worldwide compared to

approximately 58,000 at December 31, 2010. At December 31, 2011, approximately 15% of our employees

were subject to collective bargaining agreements. Based upon the geographic diversification of these

employees, we do not believe any risk of loss from employee strikes or other collective actions would be

material to the conduct of our operations taken as a whole.

Environmental regulation

We are subject to numerous environmental, legal, and regulatory requirements related to our

operations worldwide. For further information related to environmental matters and regulation, see Note 8

to the consolidated financial statements, Item 1(a), “Risk Factors,” and Item 3, “Legal Proceedings.”

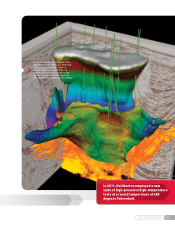

Hydraulic fracturing process

Hydraulic fracturing is a process that creates fractures extending from the well bore through the

rock formation to enable natural gas or oil to move more easily through the rock pores to a production well.

A significant portion of our Completion and Production segment provides hydraulic fracturing services to

customers developing shale natural gas and shale oil. In recent months, questions have arisen about the

scope of our operations in the shale natural gas and shale oil sectors, and the extent to which these

operations may affect human health and the environment.

We generally design and implement a hydraulic fracturing operation to “stimulate” the well, at the

direction of our customer, once the well has been drilled, cased, and cemented. Our customer is generally

responsible for providing the base fluid (usually water) used in the hydraulic fracturing of a well. We

supply the proppant (often sand) and any additives used in the overall fracturing fluid mixture. In addition,

we mix the additives and proppant with the base fluid and pump the mixture down the wellbore to create

the desired fractures in the target formation. The customer is responsible for disposing of any materials that

are subsequently pumped out of the well, including flowback fluids and produced water.