Alcoa 1996 Annual Report Download - page 11

Download and view the complete annual report

Please find page 11 of the 1996 Alcoa annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Aerospace

A Well-Timed

Expansion

Three years ago, aircraft build rates were stuck in a downcycle, well off

their 1991 peaks. Writing in Alcoa’s 1993 annual report, L. Patrick Hassey,

president of Aerospace/Commercial Rolled Products, forecast that airplane

deliveries would be picking up starting in 1996 and strengthening still

further over the next several years. He also noted a longer term growth

trend in revenue passenger miles, averaging 5% to 6% a year.

So far, the forecasts are proving, if anything, conservative. Build rates are

on course for a 44% increase in 1997 and further gains next year. In the

meantime, having anticipated the turnaround, Alcoa’s aerospace business

unit has dramatically expanded heat-treating capacity for sheet and plate.

Ready for the Turnaround

■In April of 1996, Davenport (Iowa) Works started up the largest vertical

heat-treating furnace in North America, tripling the plant’s capacity for

wide fuselage applications.

■A new horizontal plate heat-treating furnace will begin production next

month, raising the plant’s aerospace heat-treating capacity by 50% and total

heat-treated plate capacity by 30%.

■Hassey characterizes this $75 million expansion as giving Alcoa’s aerospace

customers “the most sophisticated, comprehensive heat-treat facilities and

the broadest capabilities in the world.”

■Also in 1996, a fuselage sheet polishing and processing center was opened

in Hutchinson, Kansas, offering aerospace customers just-in-time, cut-to-

size, and electronic interface capabilities on a 24-hour basis.

Internet activity on the

Plymouth Web site. The

Prowler’s aluminum body and

closure panels are made from

Alcoa sheet and extrusions and

are attached to an aluminum

frame manufactured at Alcoa’s

new Northwood, Ohio plant.

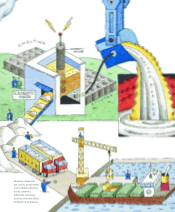

New Headquarters Going Up.

Construction is under way for

Alcoa’s new corporate center

on Pittsburgh’s North Shore.

Foundation and garage are

complete. By late spring, the

main structure will be in place

and work will be starting to

create a riverfront park facing

downtown Pittsburgh. Antici-

pated completion date of the

six-story building is June 1998.

Old Headquarters Recycled.

Alcoa has offered its present

corporate headquarters

building in Pittsburgh to the

community, as a center for

economic development. The

44-year-old landmark will

house government, private, and

academic agencies involved in

all aspects of regional planning

and growth.

9